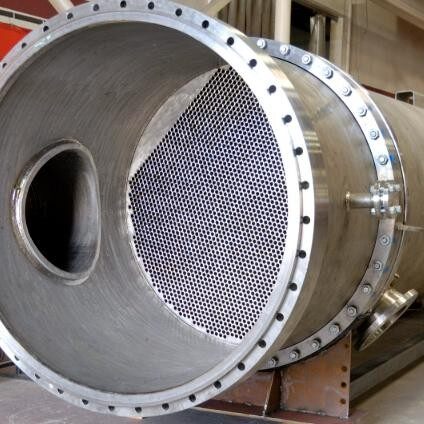

Chemical Plant Shell Tube Heat Exchanger

Products Description

The chemical plant shell and tube heat exchanger working conditions in chemical plants are often characterized by high temperature, high pressure, and strong corrosiveness of media (such as acids, alkalis, organic solvents, and sulfur-containing gases).

Products Parameter

| Parameter | Value | |

| Shell diameter | 108.06 mm | |

| Shell duct diameter | 30.00 mm | |

| Baffle type | Segmental | 25 % |

| Concave-cut | 10,15 and 20 % | |

| Baffle spacing | 43.26 mm | |

| Baffle number | 6 | |

| Heat exchanger length | 302.58 mm | |

| Tube layout | Triangular (30 | |

| Tube diameter | 15.88 mm | |

| Tube number | 19 | |

| Tube pitch ratio | 1.25 | |

Why do shell and tube heat exchangers become the "main heat exchangers" in chemical plants?

Shell and tube heat exchangers are preferred due to the following advantages:

Adaption to extreme working conditions: The shell adopts a pressure-resistant design (capable of withstanding pressures up to 30MPa) and can tolerate a temperature range of -20℃ to 600℃, meeting the high-pressure and high-temperature requirements of equipment such as chemical reaction kettles and distillation towers.

Strong material compatibility: The tube bundle and shell can be made of materials selected according to the corrosiveness of the medium (for example, 316L stainless steel is resistant to acids and alkalis, titanium alloy is resistant to seawater/chlorine corrosion, and Hastelloy is resistant to strongly oxidizing media), reducing the risk of leakage.

Controllable heat exchange efficiency: By adjusting parameters such as the number of tube bundles, tube diameter, and baffle spacing, the heat exchange area can be flexibly designed (ranging from several square meters to thousands of square meters) to meet the heat exchange needs of different production capacities (such as 10,000-ton level heat exchange in large-scale coal chemical industry).

Convenient maintenance: The tube bundle can be disassembled as a whole (such as floating head design), facilitating cleaning (to deal with scaling media, such as chemical wastewater containing suspended solids) or replacement, and reducing downtime.

High versatility: It can be adapted to various medium combinations such as liquid-liquid, gas-liquid, and gas-gas (such as steam condensation and material cooling in chemical industry), without customization for a single working condition, thus reducing procurement costs.

Core Applications

Temperature control in reaction processes: Heating materials in the reactor (e.g., using steam to heat reaction raw materials to the reaction temperature via a Plant chemical shell and tube heat exchanger) or cooling (e.g., using cooling water to remove heat generated by exothermic reactions to prevent overheating and loss of control).

Distillation and separation processes: Serving as a "reboiler" in distillation columns: heating the bottom materials to vaporize them and maintain the distillation cycle; acting as a "condenser": cooling the overhead vapor to achieve component separation.

Material preheating and energy saving: Utilizing process waste heat (such as high-temperature materials after reactions) to preheat cold raw materials, thereby reducing steam or fuel consumption.

Application Cases

Coal chemical project: In the coal-to-olefin plant of a chemical factory, the GNEE shell and tube heat exchanger is used in the "quenching tower" system. It cools the high-temperature cracked gas above 800℃ to below 300℃ (using circulating oil as the cooling medium) to avoid olefin polymerization and coking. The heat exchange area of a chemical facility shell-tube heat exchanger reaches more than 2000 square meters.

Coal chemical project: In the coal-to-olefin plant of a chemical factory, the GNEE shell and tube heat exchanger is used in the "quenching tower" system. It cools the high-temperature cracked gas above 800℃ to below 300℃ (using circulating oil as the cooling medium) to avoid olefin polymerization and coking. The heat exchange area of a chemical facility shell-tube heat exchanger reaches more than 2000 square meters.

ABOUT US

GNEE was founded in 2008 and is located at No.4-1114, Beichen Building, Beicang Town, Beichen District, Tianjin, China. It is an entity enterprise engaging in high-end industrial equipment manufacturing, focusing on the R&D, manufacturing and related technical services of industrial heat exchange equipment and pressure vessels.

Since its establishment, the company has adhered to the philosophy of "achieving customers, making employees happy; embracing changes, valuing actions; there is no best, only better". With the goal of providing one-stop services to make choices easier, it has been deeply engaged in industrial heat exchange equipment for many years and has become an excellent and irreplaceable presence in the industry.

If you require other types of heat exchangers, please visit our products and services page or email us at info@gneeheatex.com.

FAQ

Q: What about the maintenance?

A: All the goods past the test, maintenance is very easy.

Q: What is the standard of package?

A: Export standard package or special package according to customer's requirement.

Q: Why should I choose GNEE?

A: After comparing the quality, delivery, and price of the same products, you will find out the answer.

Q: Can your products be customized?

A: Considering the different sizes, materials, and heat exchange areas required for heat exchangers in different industries, our products can be customized according to your needs.